Shenzhen

Manufacturing and Supply Chain Bootcamp

David spent 6 weeks in Shenzhen with 5 other Media Lab students as part of an intensive Manufacturing and Supply

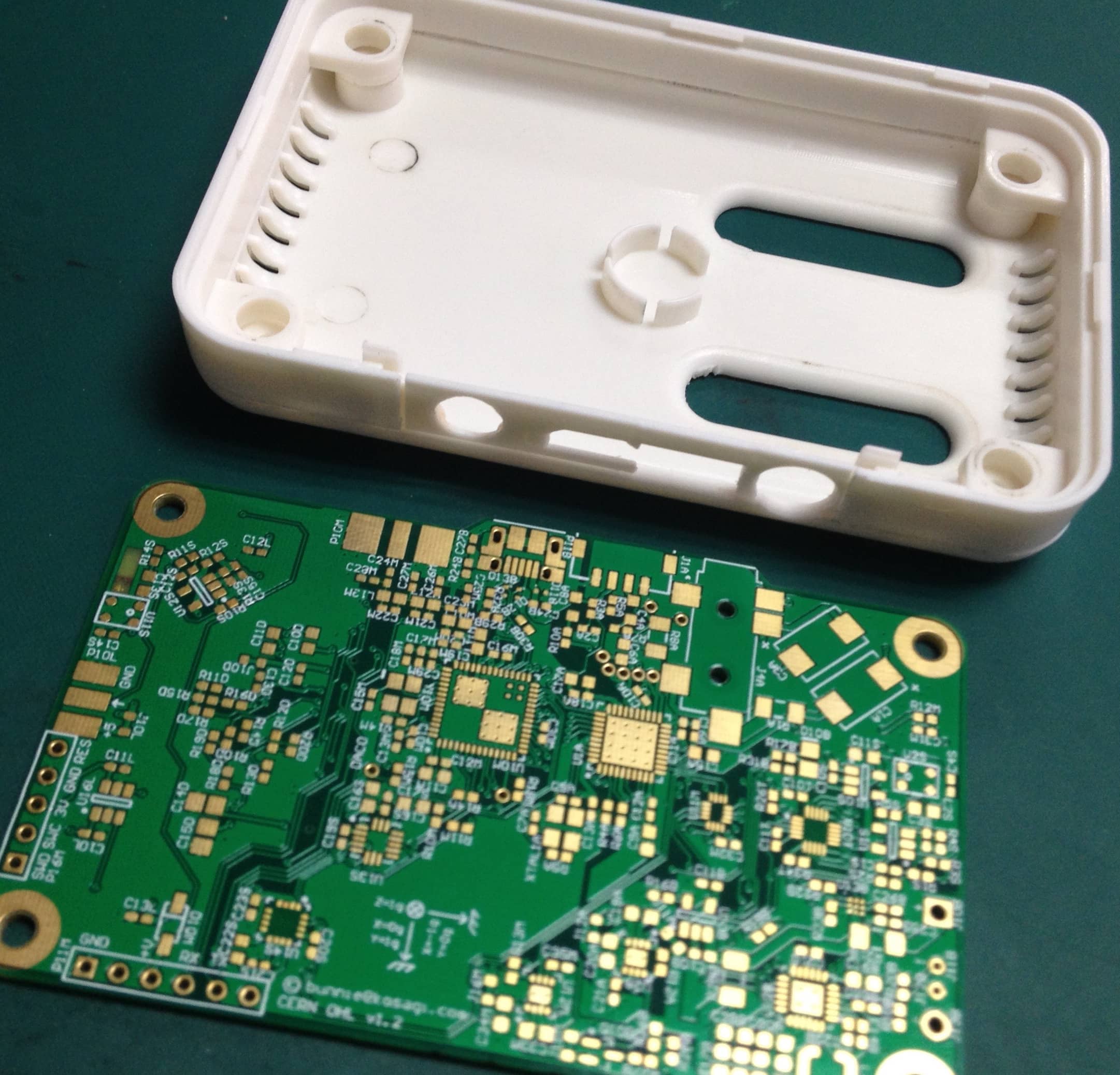

Chain Bootcamp run by bunnie Huang and xobs Cross. During the six weeks, bunnie taught them solidworks, altium,

sourcing, factory innovation, and design for manufacture. They toured thirteen factories, and were able to modify one of bunnie's designs

with their own cicuits, flexible touch interface, case design, and in-mold laminations. David added an audio stream processor

capable of noise cancelation, a CODEC, two microphone preamps, and a headphone amplifier and headphone jack. He sourced parts from the

local markets. He altered the case, redesigned the touch interface, and created a custom in-mold lamination. His final design is shown below.

During the six weeks, they sent their designs to the factories, and watched as their cases were refined (and hard-tooled)

throughout the injection molding process. They also watched small batch PCB fabrication and SMT placement.

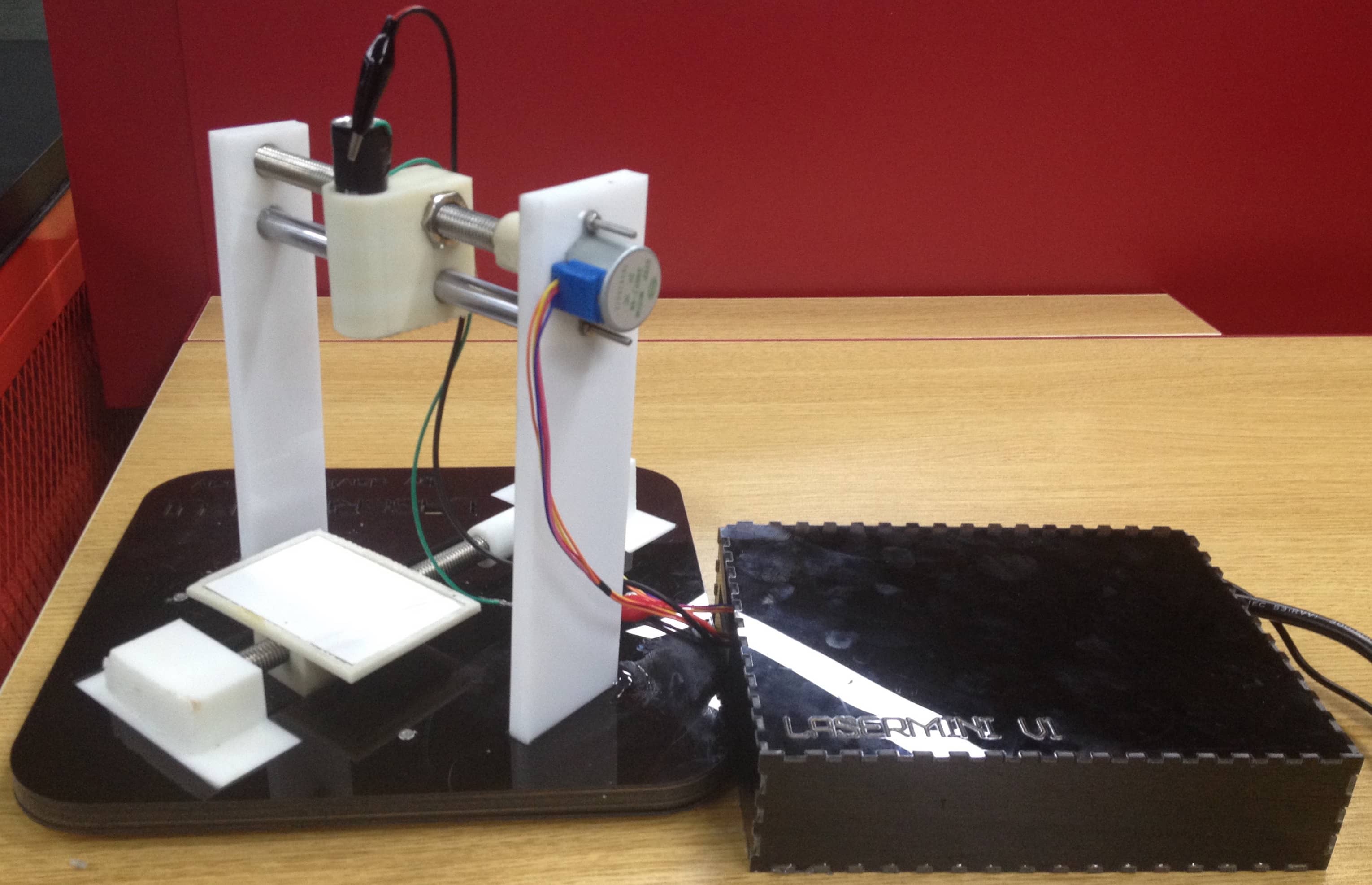

As part of the bootcamp, the participants were tasked with making something using $20 worth of parts from the local electronics markets.

Over the course of a couple days, David built a makeshift laser cutter for business cards.

David also designed Media Lab branded iPhone cases with a local factory, which he had fabricated and shipped back to the US.

David wrote about one of his factory visits in this

wirebonding factory post.